What is glutathione?

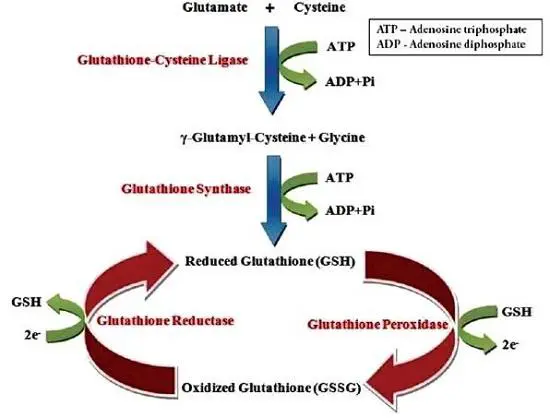

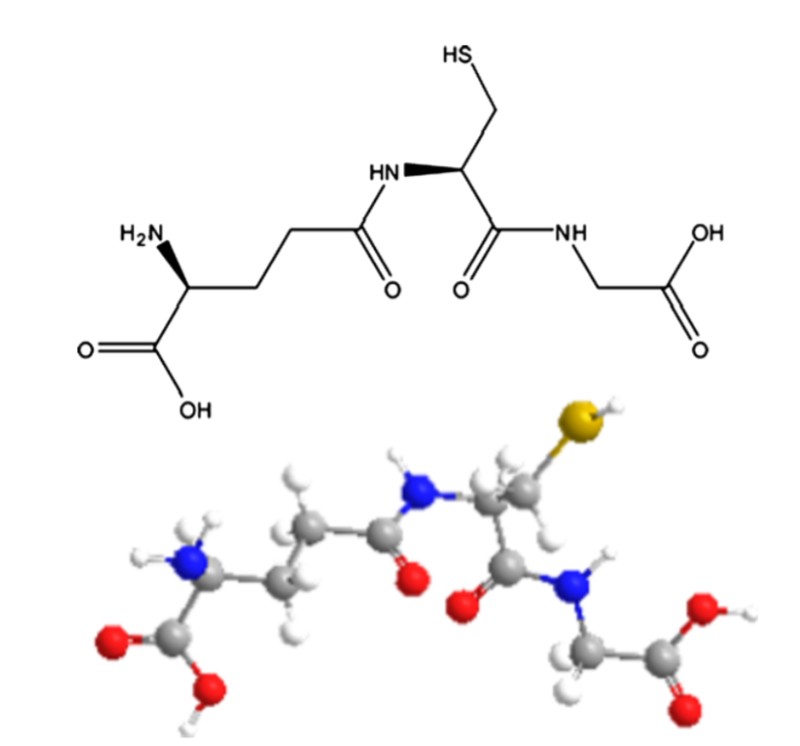

Glutathione is a tripeptide with important physiological activity, namely r-L-glutamyl-L-cysteine glycine (GSH). The thiol group on cysteine is its active group, but it can easily cause the coupling of two molecules of glutathione. Glutathione has two forms: reduced glutathione (GSH) and oxidized glutathione (GSSG). Under physiological conditions, reduced glutathione accounts for the majority, and glutathione reductase can catalyze the interconversion between the two types.

Properties and functions of glutathione

The relative molecular weight of glutathione is 307 33, melting point 189-193 ° C, crystal appears colorless and transparent in the form of long columns, with an isoelectric point of 2 83.

Glutathione is soluble in water, soluble in dilute alcohols and liquid ammonia, and insoluble in alcohols, ethers, and acetone. It is widely distributed in animals, plants, and oilseeds.

One of the functions of glutathione in cells is to resist various toxins and carcinogens.

Studies have shown that:

Glutathione can be fully absorbed in the small intestine, and some epithelial cells can use exogenous glutathione to detoxify, indicating that dietary glutathione determines the degree of cellular damage in the human body.

In addition to serving as an antidote, glutathione also has an activating effect on some thiol enzymes and can act as an antioxidant for protecting enzymes and other protein thiol groups, playing a certain role in biological oxidation, amino acid transport, and protection of hemoglobin.

Glutathione can also inhibit aging, prevent diabetes, and eliminate fatigue.

Glutathione not only enhances food flavor but also has health benefits for the human body, and its application prospects are significantly better than other types of antioxidants and preservatives.

Recent studies have also found that glutathione has the effect of inhibiting AIDS. Therefore, studying glutathione is of great significance for human health and life.

Glutathione production method

A method for producing high-purity glutathione, characterized in that the method comprises the following steps:

(1) Fermentation broth centrifugation:

Centrifuge the glutathione fermentation broth with a fermentation level of at least 1650mg/L in a tank at a speed of 3000-5000rpm for 5-10min to obtain wet yeast cell bodies;

(2) Hot water breaks the wall:

Add 1 part of wet yeast cell body into an extraction tank with 6-10 parts of boiling water, stir at a speed of 300-350rpm. When the temperature of the extraction solution reaches 85-95 ° C, hold for 10-15 minutes, stop extraction, pour out the extraction solution, and cool it to room temperature in a water bath;

(3) Extraction liquid centrifugation:

Centrifuge the extract at a speed of 3000-5000 rpm for 5-10 minutes to remove yeast residue and obtain an extract containing GSH;

(4) Adjust pH:

Add acid to the extracted solution after centrifugation to maintain the pH of the feed system at 2 In an acidic environment of 5-3.5, certain impurities can precipitate and stabilize GSH to prevent oxidation;

(5) Microfiltration:

Filter the pH adjusted extract using a microfiltration device with a pore size of 0.1 to 1 μ m to remove suspended small particle impurities and obtain a clear and transparent filtrate;

(6) Cationic resin separation:

Adsorb the filtered material solution on a sulfonic acid cation resin in an acidic environment to adsorb GSH, and then analyze it with sodium chloride or hydrochloric acid solution to obtain a liquid rich in GSH;

(7) Adsorption resin separation:

After separation and purification by cation exchange resin, the GSH rich liquid is adsorbed again on styrene based weakly polar macroporous adsorption resin, and then eluted with pure water to obtain high-purity GSH liquid;

(8) Reduced pressure concentration:

At -0 07~-0 Concentrate the GSH solution under reduced pressure at a vacuum degree of 098Mpa and a temperature of 55-65 ° C to achieve a GSH content of over 400mg/ml;

(9) Crystallization:

Add isopropanol or ethanol to the concentrated glutathione solution to achieve an organic solvent content of 60% to 80%, and adjust the pH value to 2 Crystallization is carried out in an environment of 0-4 ° C between 90 ° C and 3.0 ° C;

(10) Crystal washing:

Wash the crystals with acetone solution with a volume percentage concentration of 70% to 90%;

(11) Vacuum drying:

At -0 07~-0 Dry under a vacuum degree of 098Mpa to obtain GSH with a purity of over 98%.